Manufacturing vs. Assembly – Which Optimization Tools to Choose?

Is investing in IT technologies worthwhile for manufacturing companies? According to a Deloitte report, despite increasing economic challenges such as rising costs, manufacturers are intensifying their investments in digital technologies. Compared to 2023, last year’s technological investments in services such as:

- Cloud systems

- Artificial intelligence

- Telecommunications services, including 5G

in manufacturing companies increased from 23% to 30%.* There are many tools that can significantly streamline both manufacturing and assembly processes. What production-dedicated features in the leading ERP system, Microsoft Dynamics Business Central, can businesses rely on? This is explained by Piotr Podgórni, Director of the ERP Implementation Department at IT Vision.

Dynamics 365 Modules Dedicated to Production

Piotr Podgórni: Manufacturing companies that approach us most often use mixed processes, involving both production and assembly. In such cases, it is best to opt for an ERP system that is tailored to both types of manufacturing. An example of such a solution is Dynamics 365 Business Central, which includes both an assembly module and a production module—each serving slightly different purposes.

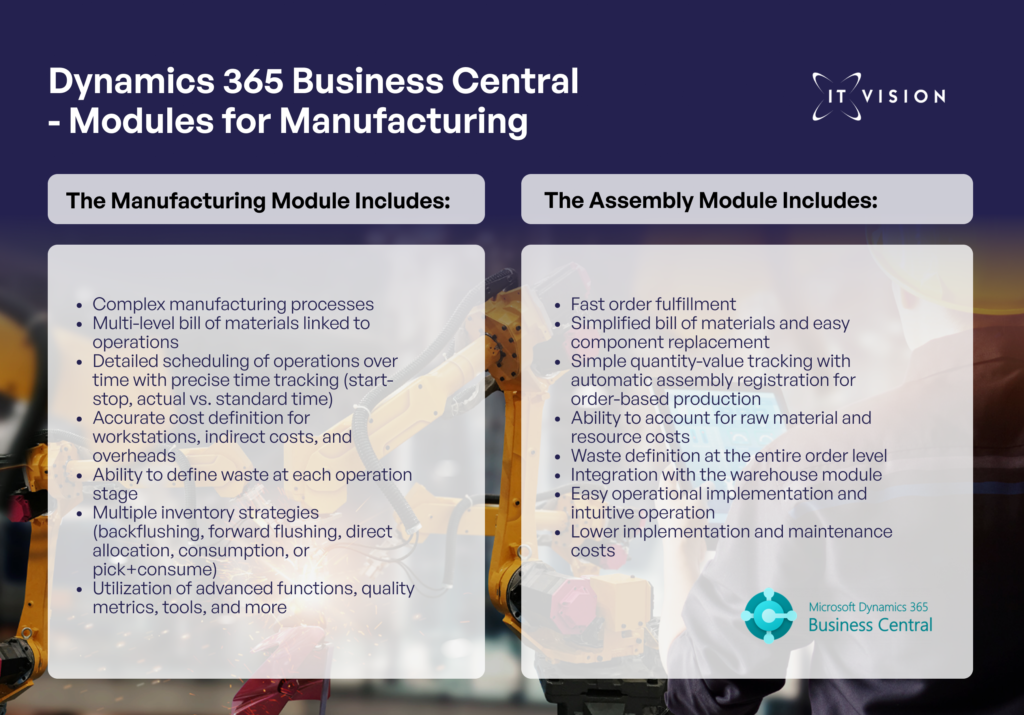

The Manufacturing Module is an advanced tool designed for enterprises engaged in manufacturing processes. It enables detailed management of multi-level production, as well as capacity planning and real-time progress tracking. Additionally, the production module is often expanded with product configurators, tools for visualizing orders/workloads, and integrations with dedicated planning (APS) and production reporting (MES) solutions.

The Assembly Module is aimed at companies that value speed and operational simplicity. It focuses on combining pre-manufactured components and fulfilling orders. In the case of order-based assembly, the creation and registration of assemblies can be automated, significantly simplifying operations.

Both modules provide multi-level bill of materials and integration with sales, planning, booking and logistics functions. They support both production to order and production to stock.

The main difference is that the manufacturing module offers more capabilities, detailed functions such as defining nests and production stations, capacity planning, setting operation times through marshals that can include set-up, start-up, waiting, transportation times, and take into account co-op handling. Thanks to the marshalling link codes, we can plan material for a specific operation rather than for the entire order – which can be particularly important in cases where the technology includes operations with long lead times.

Themanufacturing module, on the other hand, takes a slightly different approach – it focuses mainly on determining what is to be assembled (what components) – it lacks extensive planning options and production flow control, making it easier to implement and more flexible with lower operational costs. Thanks to its simple design, we can easily swap components, which gives a very high degree of flexibility, which we often use in e-commece models, where it is often the end customer who ultimately decides what goes into the purchased kit.

IT solutions for manufacturing

For manufacturing companies, choosing the right module in an ERP system allows not only to optimize production processes, but also to streamline other key areas, such as accounting, finance or project management, while maintaining data consistency across the organization.

It’s also worth extending a classic ERP system with dedicated manufacturing tools that easily integrate with Dynamics 365, expanding its capabilities.

Examples of tool applications from the point of view of manufacturing companies:

- Detection of risk of failure (CMMS+EAM 4FACTORY with additional AI module 4FACTORY).

- Detection of energy consumption anomalies over time (SFC 4FACTORY with additional AI 4FACTORY module)

- Advanced business analysis – sales and production forecasting (Item Intelligence from Data Courage).

If you are interested in solutions for manufacturing, contact us!